As optionally substituted with petrol engine or diesel engine application for driving the conveyor are included.

|

Technical Specifications

|

|

|---|---|

|

Capacity :

|

60m3/h

|

|

Conveyor Length :

|

10m

|

|

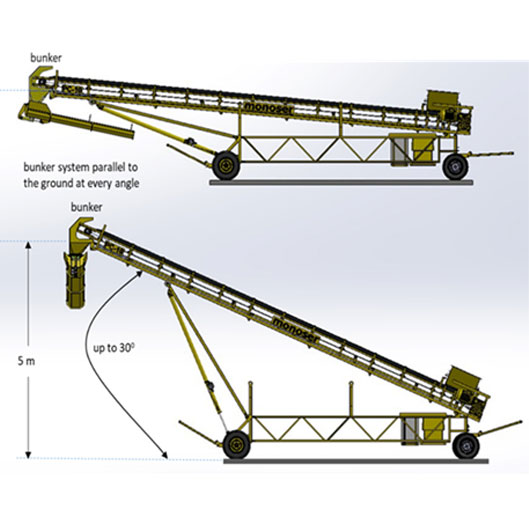

Maximum Slope :

|

30°

|

|

Maximum Unloading Height :

|

5m

|

|

Groove Length :

|

3x80cm = 240cm

|

|

Vertical Movement of Conveyor :

|

Hydraulic

|

|

Groove Vertical Movement :

|

Hydraulic

|

|

Working Temperature (°C) :

|

-20 ~ 48

|

|

Groove Horizontal Motion :

|

Manuel

|

|

Motor :

|

10 kW, 3 phases,190-200V or 380-400V (According to the electrical voltage of the country)

|

monoser® PC10, some the production of prefabricated elements is the preferred cost-effective solution for applications such as concrete casting in low-rise buildings.

By combining modern design elements such as finite element analysis and structural optimization, our conveyor system have a more intelligent structure, lighter weight in its class, and longer service life.

monoser® PC 10 has special design chassis construction that is all tubular steel welded. It undergoes the necessary structural test in order to guarantee their durability, safety, and reliability.

monoser® PC 10 has a light and resistant structure. Each section is a welded box lattice frame designed to carry the loads applied to it.

Conveyor belt is supported by fully U-troughed rollers for increased capacity and cleanliness.

PC10 has a special bunker system that is parallel to the ground at every angle of the conveyor belt.

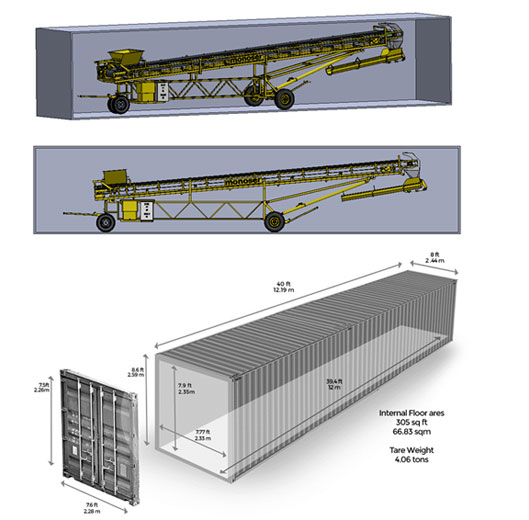

1×40 High-Cube Container

English

English