4X4 Remote Controlled Self Traction Concrete Placing Distributor (Towable)

|

Technical Specifications

|

|

|---|---|

|

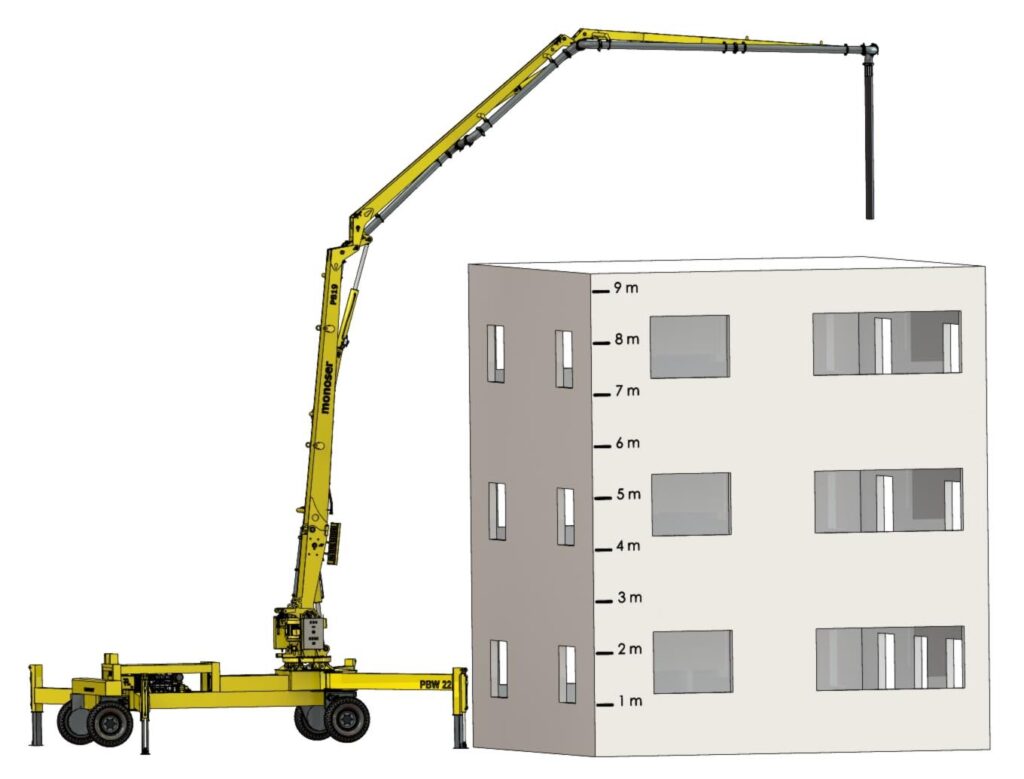

Vertical Reach of the distributor :

|

22 m

|

|

Horizontal Reach of the distributor

|

19 m + End Hose

|

|

Placing diameter (without end-hose)

|

38 m

|

|

Concreting area

|

1.134 m2

|

|

Number of distributor segments

|

3

|

|

Distributor type

|

R Folding

|

|

Counter-weight

|

Without Counter-weight

|

|

Remote Control System

|

Wireless, Fully proportional joystick remote control.

|

|

Traction System

|

4x4 hydrostatic traction, Cross-linked double circuit.Only For job site positioning.

|

|

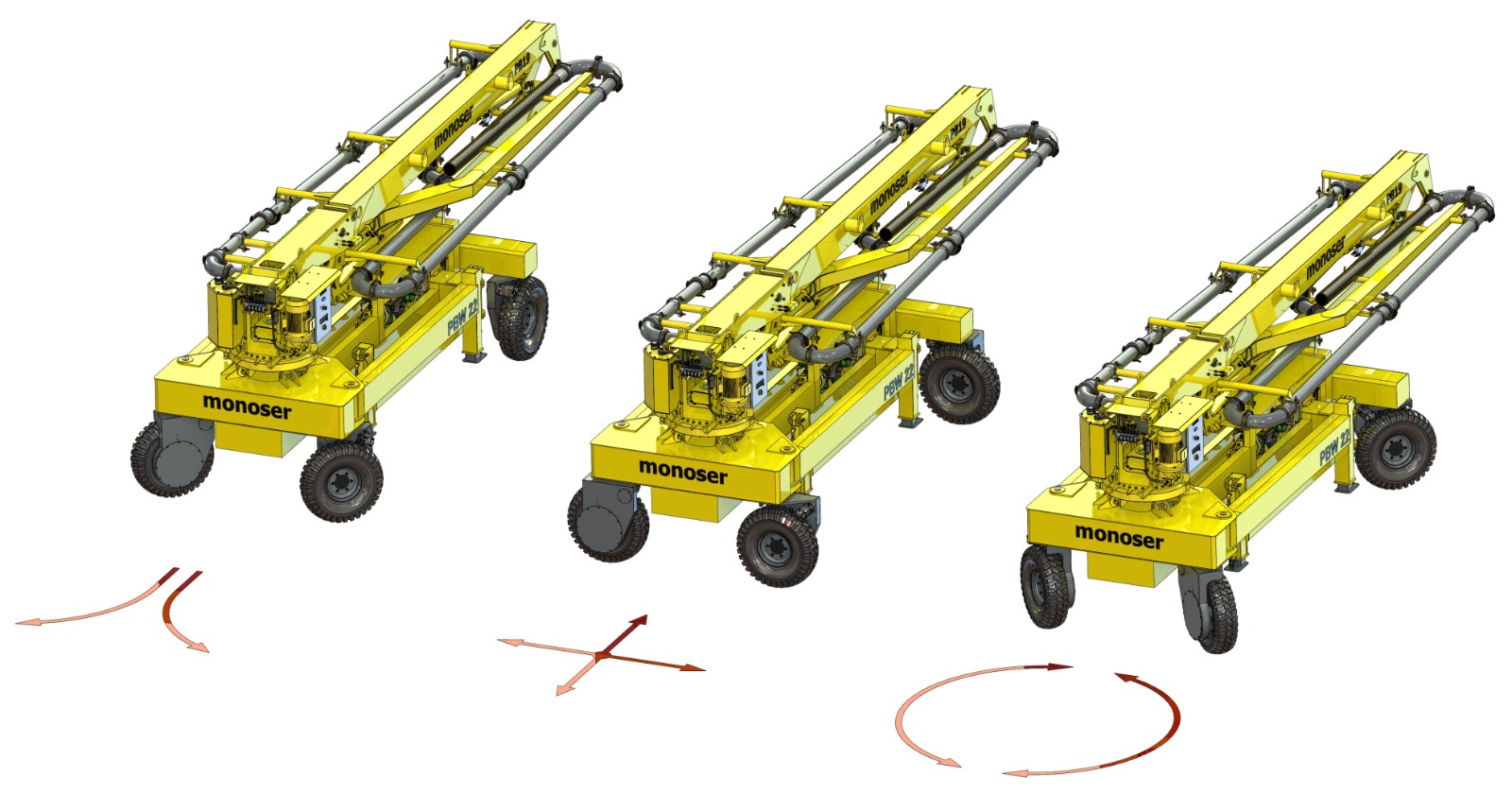

Steering System

|

4x4x4 and 180º full crab steering, standard front axle steering, parallel crab, cross-crab.

|

|

Wheel Alignment

|

Automatic self alignment.

|

|

Diesel Engine

|

KUBOTA 44KW, water cooled, Stage 3A, Tier 4

|

|

Electric motor

|

7,5 kW, 380-400V, 3-Phase

|

|

Distributor weight

|

2,6 t

|

|

Total Machine Weight

|

8 t

|

|

Concrete piping

|

Standard 5,5” (Ø125 ID) pipes

|

|

Flexible end hose

|

3 m

|

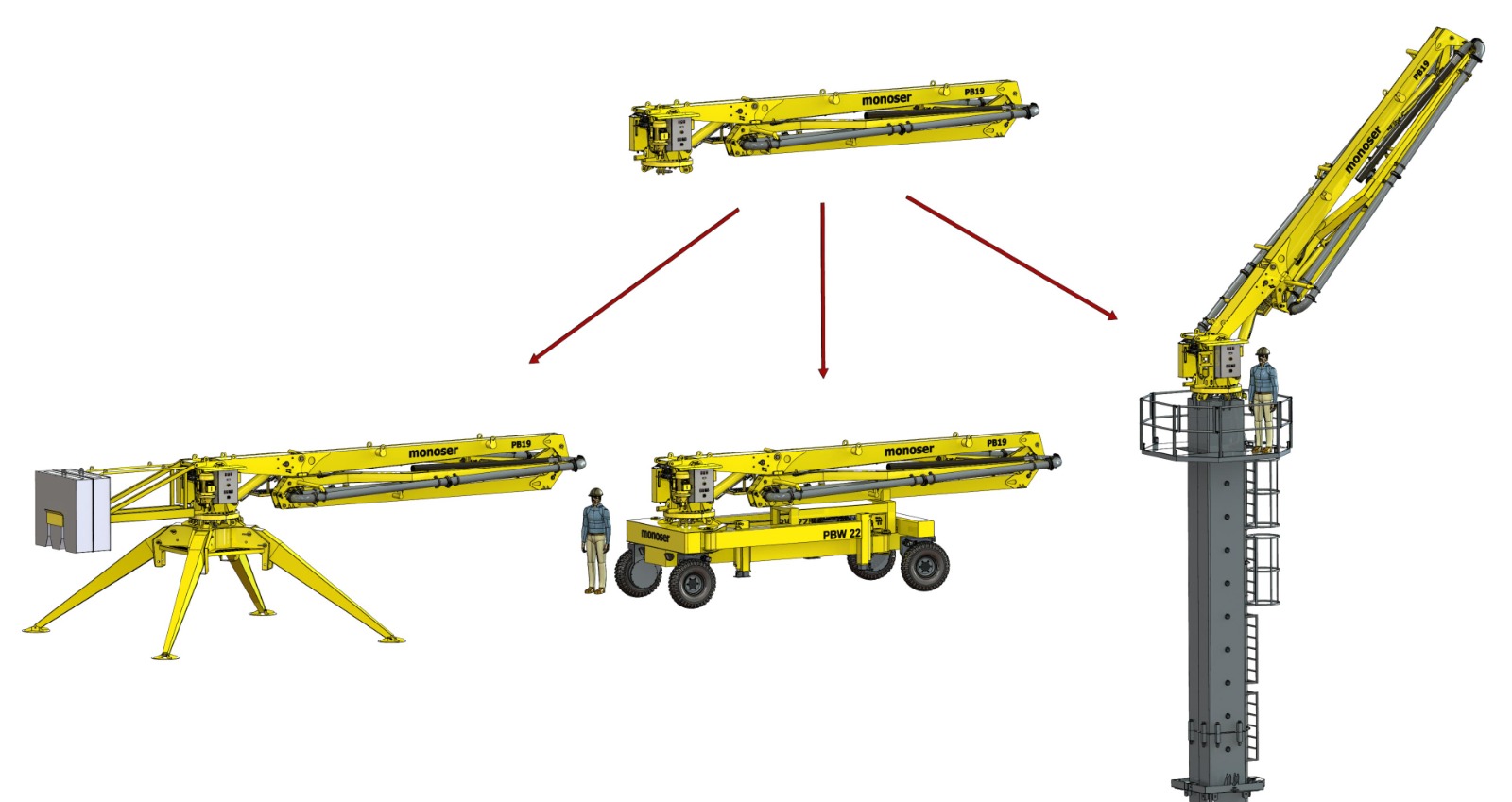

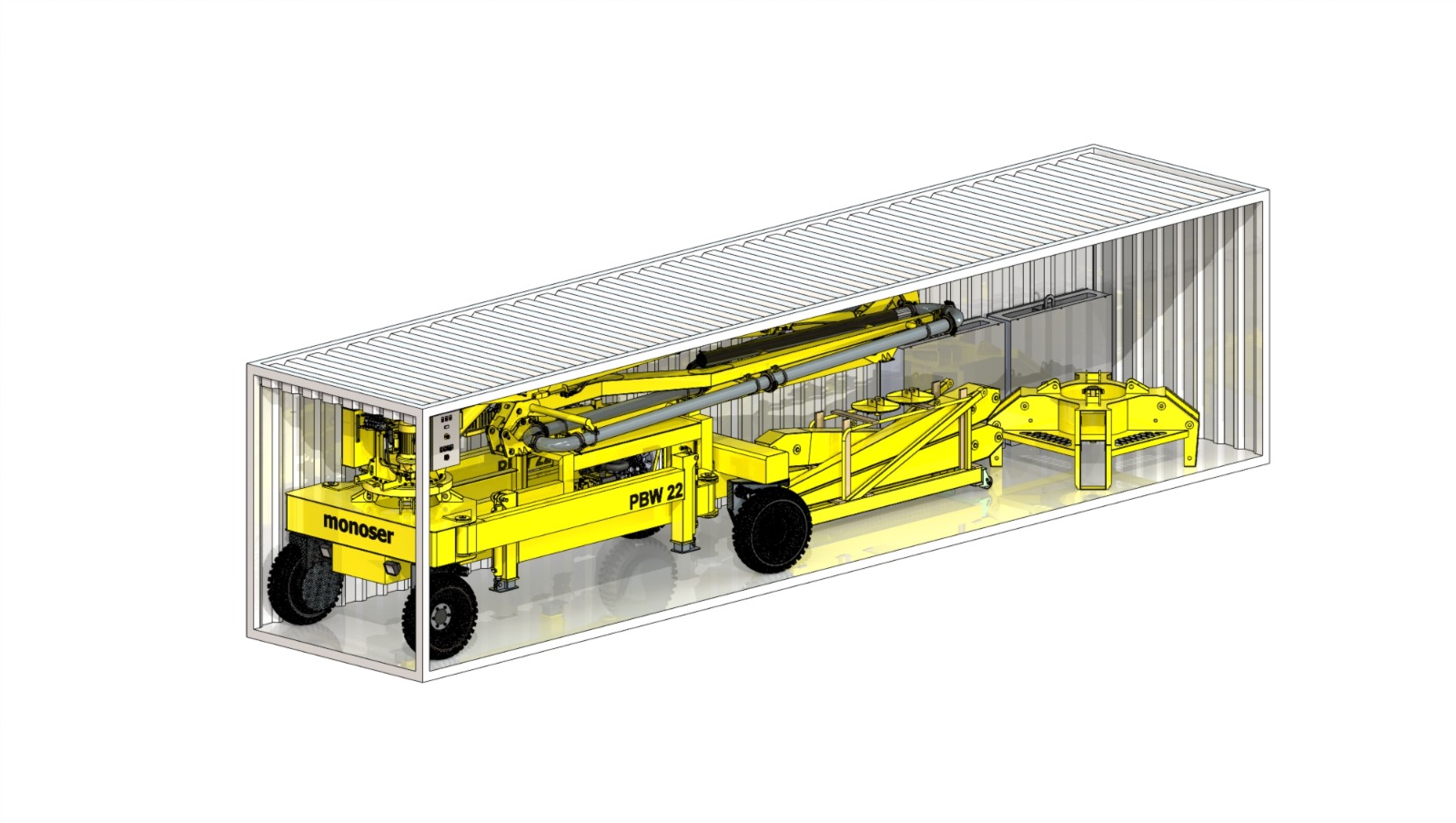

PBW22 is a combination of remote-controlled self-traction chassis and PB19 Hydraulic Concrete Placing Distributor. Distributor section can work by the diesel engine of the chassis or by electricity. You can separate the distributor away from the chassis and put it on a four-leg pedestal or self-climbing mast.

PBW22 has not only 4×4 hydrostatic traction, but it has 4-wheel steering. Thanks to the full crab steering, PBW22 is capable of standard front axle steering, parallel crab, cross-crab. This feature is unique in the market.

Hydraulic power pack and electric control panel are located on the rotating tower. In that way the distributor is used without counterweight and power pack on the tail. All the maintenance works are made easily on the service platform.

Due to the slip ring mechanism on the rotating tower, in electric use, electric cable does not need to be wrapped around the machine. The operator can turn the distributor as much as it is needed. The electric cable of the distributor become safe against cable cut risks.

monoser®️ concrete placing distributors has been designed in “Split” considering the lifting capacity of the construction site crane So end user can easily installed/disassembled in any location. We provide the best values in the sector for the heaviest part of the machine. The heaviest part of the monoser®️ concrete placing distributor is lighter than the competitors. With the site crane the end user can set up the distributor at the farthest point.

Thanks to the design of this system the operator or technicians can easily reach the main components to make maintenance or repairment easily.

English

English