|

Technical Specifications

|

|

|---|---|

|

Max. Concrete Outlet (ROD Side) :

|

71,2 m³/h

|

|

Max. Concrete Compression Pressure (ROD Side) :

|

63,2 bar

|

|

Max. Concrete Outlet (PISTON Side) :

|

49,2 m³/h

|

|

Max. Concrete Pressing Pressure (PISTON Side) :

|

98,8 bar

|

|

Shipment Roller :

|

180 Ø mm

|

|

Delivery Roller Stroke :

|

1200 mm

|

|

# Stroke (ROD side) :

|

38,9 Str./min

|

|

# Stroke (PISTON side) :

|

26,8 Str./min

|

|

Max. Aggregate Size :

|

38 mm

|

|

Heavy-Duty S Tube :

|

180 – 125 mm

|

|

Outlet Diameter :

|

125 mm

|

|

Engine :

|

Cummins QSF F3.8 134 HP Stage V / Tier 4F 4 Cylinder, Turbocharged, Water Cooled

|

|

Engine Power :

|

100 (134) kW(hp)

|

|

Fuel Tank :

|

110 Lt

|

|

Self-Traction 4×4 (only use for construction site) :

|

Max. Speed 4,3 km/h

|

|

Main Pump Unit :

|

Kawasaki (Japan)

|

|

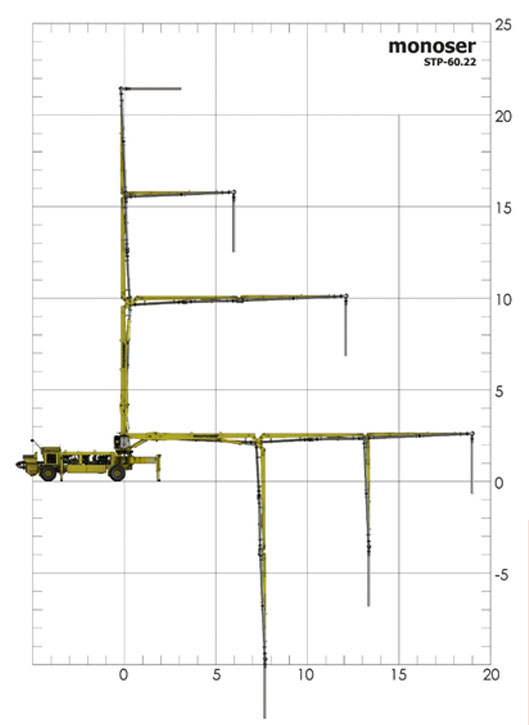

With Hydraulic Boom Max. Vertical Concrete Discharge :

|

22 m

|

|

With Hydraulic Boom Max. Horizontal Concrete Discharge :

|

19 m

|

|

Rotary Tower Slewing Range :

|

360°

|

|

Concrete Pipes :

|

5,5” (Ø125 mm)

|

|

End Hose :

|

3 m

|

The new, compact monoser® Scorpion STP60.22C concrete pump is preferred in projects that require cost effective solutions such as road construction, tunnel construction, dam construction and multi-storey building construction, villa construction.

It has a lighter, more durable chassis using finite element analysis and in this context, it has a longer service life that is more compatible with construction area.

They are less costly than truck-mounted pump + distributor systems. They can be deployed more comfortably than the truck-mounted systems under conditions of limited construction areas.

English

English